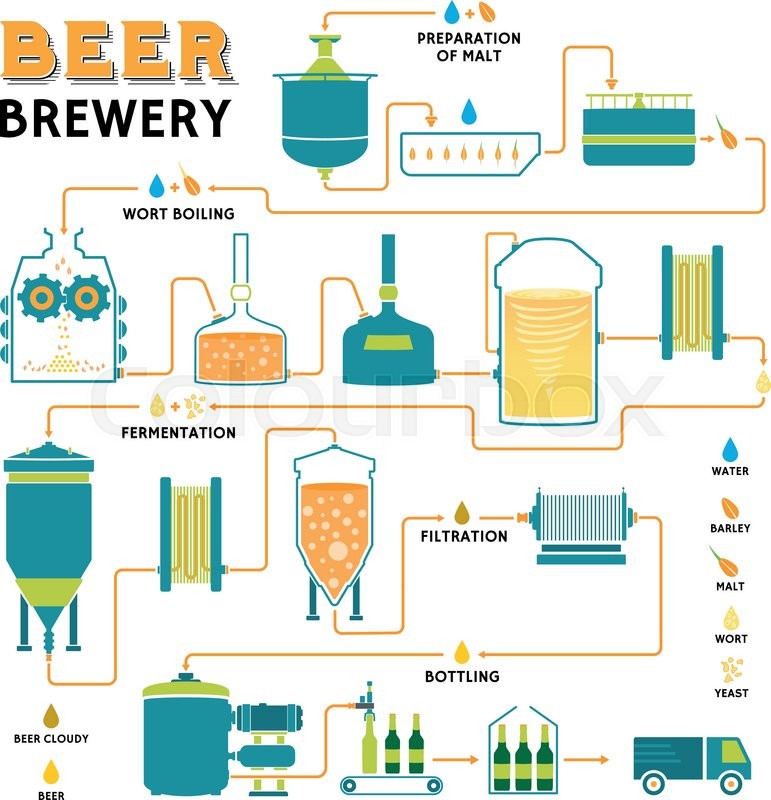

The following diagram illustrates the process of craft brewing. Craft

Beer Manufacturing Process Flow Chart Pdf

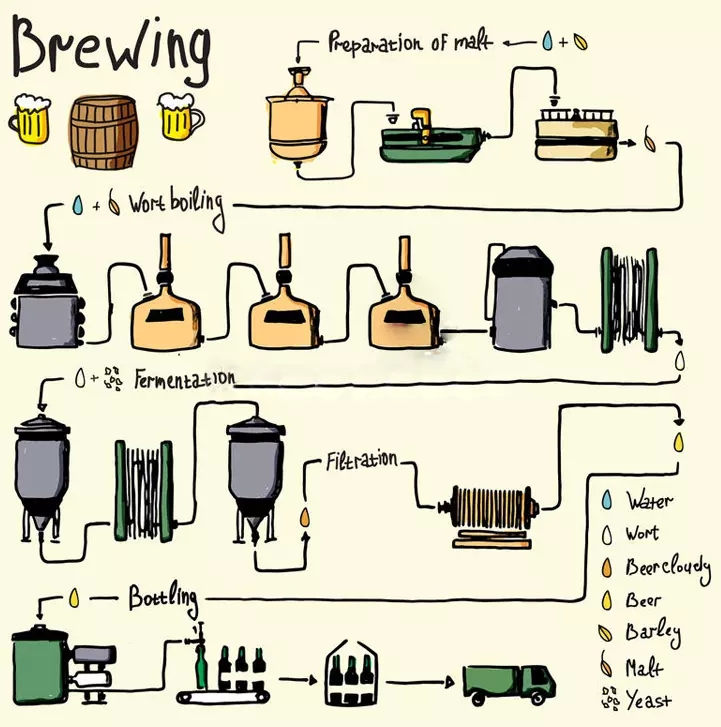

The Brewing Process Diagram. Today's infographic is another diagram of the Brewing Process, this one from the Beer Masons, a beer appreciation society in Australia. Click here to see the diagram full size. One interesting addition is they point out that beer is known by many names in the process from grain to glass, and list them in a flowchart.

Beer production process with flow chart.bmp (1027×665) Craft brewing

Flottweg decanters, Sedicanters®, and separators increase brewing process efficiency: The Flottweg decanter separates up to 75% liquid wort from the separated hot trub and returns it to the brewing process. The same is also true for dry-hopped beers: when the decanter is used in the cold process to separate the spent hops, it will reduce wort and beer losses.

[DIAGRAM] Plumbing Diagrams For Brewing Beer

Download scientific diagram | Flowchart of brewing process. from publication: Antioxidant Content of Aronia Infused Beer | Beer is a fermented beverage in which antioxidants can contribute to the.

Brewery process vector illustration. Labeled beer ale making process

The process can seem overwhelming to beginners, but by the end of this article, you'll know just how to kickstart your homebrewing journey. Keep reading this step-by-step guide to learn more about brewing your own lager beer. 1. Brew the Lager . Brewing involves two terms you need to know: the mash and the wort.

Learn How The Brewing Process Works The Driftwood Spars Brewery

The Easy Beer Brewing Process Flow Chart. Now that you have a basic understanding of the key components of beer brewing, let's dive into the easy beer brewing process flow chart. Follow these simple steps to brew your own homemade beer: 1. Step 1: Gather Your Equipment. Before you begin the brewing process, make sure you have all the necessary.

Beer Manufacturing Process Flow Chart Pdf

Beer Making Process Flow Example [classic] Use Creately's easy online diagram editor to edit this diagram, collaborate with others and export results to multiple image formats. You can easily edit this template using Creately. You can export it in multiple formats like JPEG, PNG and SVG and easily add it to Word documents, Powerpoint (PPT.

Beer Brewing Process, Craft Beer Brewing, Coffee Brewing, Brewing

A process flow diagram (PFD) is a diagram commonly used in chemical and process engineering to indicate the general flow of plant processes and equipment. This PFD shows the process of brewing beer. Download EdrawMax and start creating PFD diagrams. Learn more details from this diagram,, or try to make yours with ease now!

Beer brewing process brewery factory production Vector Image

We would like to show you a description here but the site won't allow us.

The following diagram illustrates the process of craft brewing. Craft

The Basic Process. In all-grain brewing, crushed malted grains are soaked in hot water, typically in a range of 145-158°F, for 1 hour to extract the grain's sugars. This process is known as mashing. The fermentable sugary liquid, called wort, is drained (lautered) to the boil kettle, leaving the spent grains behind.

Beer brewing process infographic. In flat style. Vector illustration

Contrary, you can use low or bottom fermentation to make beers with a low percentage of alcohol. This fermentation takes about ten days because the lager yeast is active at a low temperature of 39.2 to 53.6 F (4 - 12 C). In such a case, yeast will settle to the vessel's bottom after the process is complete. Step 4.

Beer brewing process infographic flat style Vector Image

Beer Production Process - Malting and Brewing. The main objective of beer making process, which involves lots of steps, is to convert the grain starch from germinated seeds to the sugar and extract this sugar via water, and then let it ferment with yeast to obtain the final product of an alcoholic, carbonated drink. The steps generally involve: Malting, milling, mashing, extract separation.

Flow diagram summarizing beer production and exit of wastes. (1

First, properly sanitize everything that will come in contact with the beer. Then add the priming sugar to the empty bottling bucket. Rack the beer to the bottling bucket from the secondary fermenter, which will also mix the two. Then attach the tubing that you use for racking to the spigot on the bottling bucket.

Easy Steps to Brewing Beer 2023 AtOnce

Jun 2020. Demetri Petrides. This SuperPro Designer example analyzes a generic brewery that produces 126,000 L of beer per day (5% alcohol by volume). The results include material and energy.

Beer Production Process MarietinSchmitt

There are a few different ways to make beer, but the most common method is the two step process. The first step is to make the wort, which is the liquid that will become beer. The second step is to ferment the wort, which turns it into beer. Beer production process flow chart and introduction. Step 1 - Malt Milling

How to make craft beer?

With a meticulously designed flow chart for brewing beer, you embark on a journey through the essential steps that lead to the creation of a flavorful and aromatic brew. Beer making involves a series of carefully coordinated processes that transform basic ingredients into a complex and delightful beverage. Take a look at the table below to get.

Beer Making Process Flowchart

Download scientific diagram | Flowchart and mass balance of the beer brewing process. from publication: Craft Brewery Wastewater Treatment: a Fixed-Bed Single-Batch Reactor with Intermittent.